What are common causes of oil contamination?

Oil is often underestimated as a critical component in engine performance. However, clean, filtered engine oil is essential for the longevity and functionality of all turbochargers.

Causes of oil contamination:

- Damaged or Poor-Quality Oil Filters: Ineffective filters can allow debris into the oil supply.

- Excess Moisture: Leads to premature oil degradation, increased corrosion, and higher wear rates.

- Carbon Build-Up in the Engine: Quickly contaminates fresh oil.

- Accidental Contamination During Servicing: Mishandling can introduce dirt into the oil.

- Unchanged Oil: Old oil with detergent deposits becomes abrasive, damaging turbo components.

- Degraded Oil from High Temperatures or Extended Service Intervals: Reduced lubrication effectiveness.

- Internal Engine Leaks: Mixing fuel or coolant with the oil supply compromises oil quality.

- Residue from Blasted Components: Leftover particles from the remanufacturing process.

- Particles from Carbon Build-Up in Oil Feed Pipes: Enter the oil flow and harm the turbocharger.

Signs of Oil Contamination:

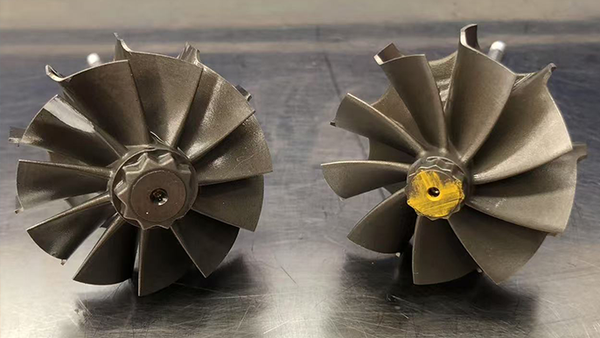

- Scoring on Thrust Components: Evidence of abrasive damage.

- Scoring on Journal Bearings: Indicates foreign particles in the oil.

- Scoring on the Journal Bearing Diameter of the Shaft and Wheel: A clear sign of contamination.

- Fuel Smell in the Oil: Indicates internal leaks or contamination.

- Particulates in the Oil: Visible debris that compromises lubrication.

Preventing Turbo Failure from Oil Contamination:

- Use New Oil and Filters: Always opt for filters recommended by the engine manufacturer.

- Clean or Replace Oil Inlet Pipes and In-Line Micro Filters: Prevent carbon deposits from entering the oil supply.

- Handle Oil Carefully During Servicing: Avoid accidental contamination.

- Inspect for Engine Wear: Look for swarf deposits or other potential contaminants.

- Maintain Regular Servicing: Ensure the vehicle is up to date on service intervals.

Pro Mechanic Tip:

Low oil levels or using the wrong oil grade can also lead to turbo failure. If the root cause of the failure isn’t identified and addressed, the remanufactured turbo is likely to fail in the same way. Remember, catastrophic damage to the turbo’s bearing systems can occur within seconds of operation if oil quality or levels are inadequate.